Understanding Soldering Tools

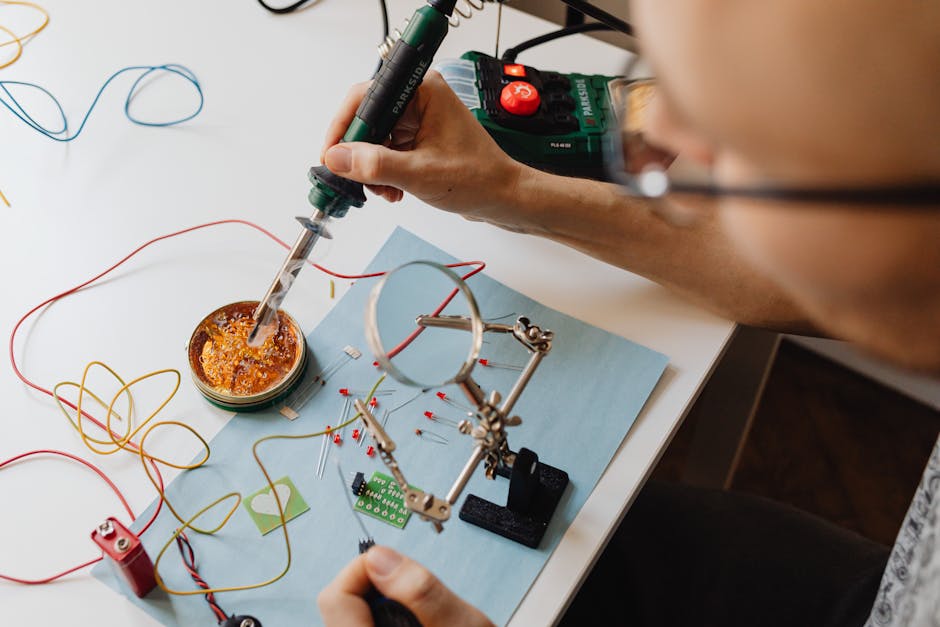

Soldering tools are essential for joining metals by melting solder, but they can be dangerous if not used correctly. Understanding the different types of soldering tools, such as soldering irons, soldering guns, and soldering stations, is crucial before attempting any soldering work. Each tool has its own unique features and uses, so it’s important to choose the right tool for the job at hand.

The soldering iron, the most common tool, consists of a heated metal tip that melts the solder to create a strong joint. On the other hand, soldering stations offer adjustable temperature controls, ideal for delicate electronic components. Soldering guns are another option, often preferred for larger, more demanding soldering tasks. Being familiar with how each tool operates ensures safe and effective soldering results.

Before diving into soldering projects, take the time to read the user manual of your soldering tool. The manual provides vital information on proper usage, maintenance, and safety precautions. Additionally, familiarize yourself with the various parts of the soldering tool, such as the tip, heating element, and power source. Knowing how each component functions increases your overall safety and efficiency when soldering.

Always remember to inspect your soldering tools before each use. Check for any signs of damage or wear, such as frayed cords, cracked handles, or loose tips. Using damaged tools can lead to safety hazards, including electrical shocks or fire. By regularly inspecting and maintaining your soldering tools, you ensure a safer working environment and prolong the lifespan of your equipment.

Safety Precautions Before Use

Before starting any soldering project, it’s crucial to follow specific safety precautions to prevent accidents and injuries. Proper ventilation is essential when soldering to avoid inhaling harmful fumes emitted during the soldering process. Working in a well-ventilated area or using a fume extractor helps maintain a safe breathing environment.

When setting up your soldering station, ensure it is placed on a stable, heat-resistant surface, away from flammable materials. Keep a fire extinguisher nearby in case of emergencies. Additionally, always wear appropriate personal protective equipment, such as safety goggles and heat-resistant gloves, to protect yourself from potential burns and eye damage.

Avoid wearing loose clothing or dangling jewelry that could accidentally come into contact with the soldering tool and cause burns or accidents. Tie back long hair and roll up sleeves to minimize the risk of getting caught in the soldering iron. Maintaining a clutter-free workspace reduces the chances of accidental spills or burns, creating a safer soldering environment.

Before plugging in your soldering iron, double-check that the power switch is turned off to prevent accidental activation. Once powered on, handle the soldering tool with care, keeping it away from flammable materials and other heat-sensitive objects. Always unplug the soldering tool after use and allow it to cool down completely before storing it away.

Safety Measures During Soldering

While soldering, stay focused and avoid distractions to prevent careless mistakes that could result in accidents. Concentrate on the task at hand and maintain a steady hand when working with the soldering tool to create clean and secure solder joints. Rushing through soldering projects increases the risk of errors and potential injuries.

Position your soldering iron in a secure holder when not in use to prevent accidental burns or damage to the work surface. Avoid touching the hot tip of the soldering iron with bare hands, as it can reach high temperatures and cause severe burns. Use a heat-resistant mat or stand to place the soldering tool on during breaks or when not actively soldering.

Be cautious when handling molten solder, as it can cause burns upon contact with the skin. Use soldering aids like tweezers or clamps to hold small components in place while soldering to avoid accidental burns. Always work in a controlled manner, ensuring that the soldering tool is used safely and efficiently to complete the soldering task at hand.

In case of any accidents or burns during soldering, immediately rinse the affected area with cool water and seek medical attention if necessary. Keep a first aid kit handy in your workspace for quick response to minor injuries. Prioritizing safety measures during soldering not only protects you from harm but also promotes a secure and accident-free soldering experience.

Post-Soldering Safety Tips

After completing a soldering project, let the soldering tool cool down before storing it away. Properly clean the soldering iron tip to remove any residue or oxidation buildup, ensuring consistent performance for future use. Store your soldering tools in a dry and safe location, away from children or pets to prevent accidents or mishandling.

Dispose of used soldering materials, such as solder wire or flux, according to local regulations to avoid environmental contamination. Always wash your hands thoroughly after handling solder to remove any residue and prevent accidental ingestion. By following these post-soldering safety tips, you maintain a clean workspace and reduce potential risks associated with leftover materials.

Regularly inspect and maintain your soldering tools to ensure they remain in good working condition. Replace worn-out parts or components promptly to prevent malfunctions or safety hazards during future soldering projects. By keeping your tools well-maintained, you ensure optimal performance and safety each time you engage in soldering activities.